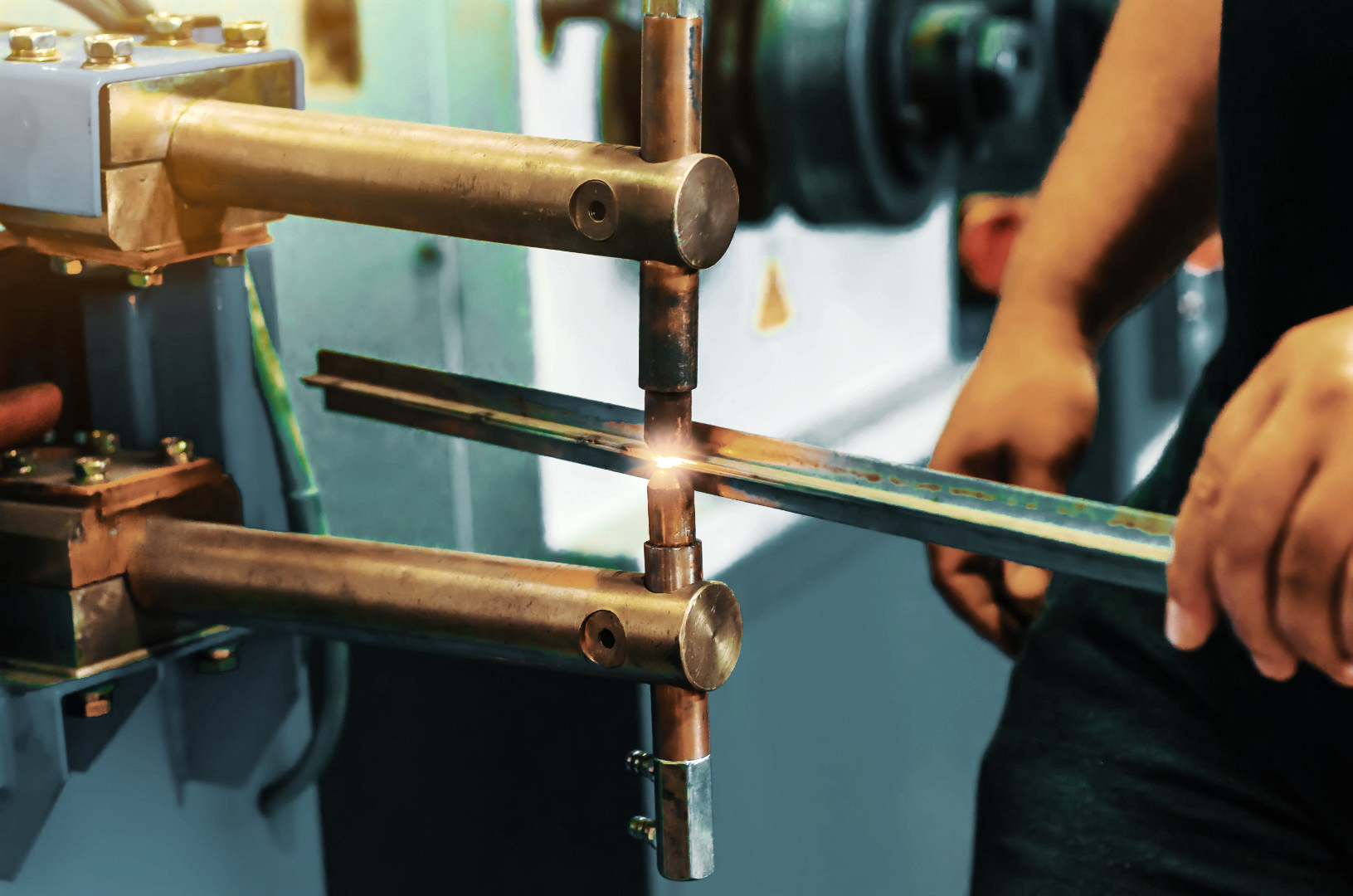

Welding, in all its forms, requires precision and patience. Issues that plague manufacturers can usually be sidestepped through adherence to checklists and careful maintenance, but sometimes problems arise despite our best-laid plans. We’re here to help you troubleshoot potential issues with your welds, inform you of why these defects arise, and what you can do to fix and/or prevent them.

In a study of common welding defects and causes of poor weld quality, the most common factor by far was fixture errors, but issues can arise from the power supply, part geometry, and a number of other variables. Some of the more common ones are listed below.

1. Electrode Wear

Deformation of electrode tips can occur over time as a result of use, but if the wear seems unusually fast, there are a number of potential factors that could be impacting the rate of degradation.

- High Weld Current - If the current is too high for the combination of parent metal and electrode, one could expect to see expulsion, increased surface indentation, and electrode wear. If this is the case, use a current analyzer to adjust accordingly.

- Dirty Materials - any contaminants on the surface or coatings can cause inconsistencies and increase electrode wear. Careful cleaning of work surfaces and base metals should reduce contamination.

- Insufficient Cooling - Inadequate flow or plugged lines can prevent the coolant from reaching the inside surface of the electrode face. If the electrode is not cooled properly its life will definitely be shortened.

2. Weld Quality

Inspection of assemblies for the number and quality of welds may reveal unstable or unsatisfactory weld quality. Missing welds and low weld quality can lead to unstable bonds and failure of assembled components, so it’s important to review and test components after they’ve been welded. This can be done by a combination of visual and, if specified, destructive tests. Many different factors can cause weld quality issues:

- Low Weld Current - if sufficient temperatures aren’t reached, the two metals may not be fused and the weld may fail.

- Poor Electrical Connection - loose cables or connections, contaminants, or oxidization can impede current flow, causing the weld to fail.

- Equipment Failure - if the current analysis shows no issues, examination of the mechanical system should commence. The electrode may not have contacted the parent metal at all, or the cylinder or servo could be functioning improperly.

3. Excessive Indentation

Indentation beyond weld specifications indicates improper welding conditions and should be addressed. Potential causes that should be checked to help reduce indentation are:

- Electrode Faces Must Be Parallel - When electrodes are not aligned parallel to the workpiece, a host of problems can arise, one of which is excessive indentation.

- Poor Part Fit - If the metals being welded don’t mate up and fit together, the force can cause distortions in the parent metals. This misalignment can allow for indentation of the weld site.

- Weld Time Too Long - if currents are passed through the metal for too long, it can cause warping in the parent metals, even if temperatures remain in an optimal range.

4. Oxide Contamination

Oxide buildup in the weld area can cause inconsistencies by preventing contact at the weld joint. There are a number of issues that could be causing said oxidization.

- Unclean Workpieces - particulate contamination can affect the dispersion of oxides in the weld area and electrode face.

- Low Weld Force - If the weld force is too low, it may not push the oxides out of the way and create consistent bonds between the parent metals.

- No Cover Gas - if the oxide buildup continues to be an issue, using a cover gas can help eliminate the presence of oxides in the weld site.

5. Expulsion

While easily detectable, expulsion can be a result of a variety of factors and can seriously impact the consistency of welds. It’s important to identify the root cause and manage it quickly.

- High Weld Current - If the weld current is too high, expulsion may not be the only issue you experience. If not managed properly, arcing, short-circuiting, and equipment malfunctions can result as a consequence of expelled material accumulating on machine components.

- Poor Part Fit - if the parent metals are not aligned or contacting correctly, the weld force may distort the metals, causing expulsion.

- Poorly Applied Sealer - Misapplication of sealers or adhesives, either through misplacement or excessive amounts, can cause the weld force to be improperly applied, resulting in expulsion and burn-through.

While not a complete list of the issues that manufacturers and welders see, these represent some of the most commonly seen and easily fixable problems. Manufacturers have tools and tests at their disposal to limit the number of times issues arise and the impact they can have on production down the line. It is important for safety and financial stability to abide by these standards.

Be sure to look out for future articles covering all aspects of resistance welding, and check out our social media profiles to get in on the conversation as it’s happening!