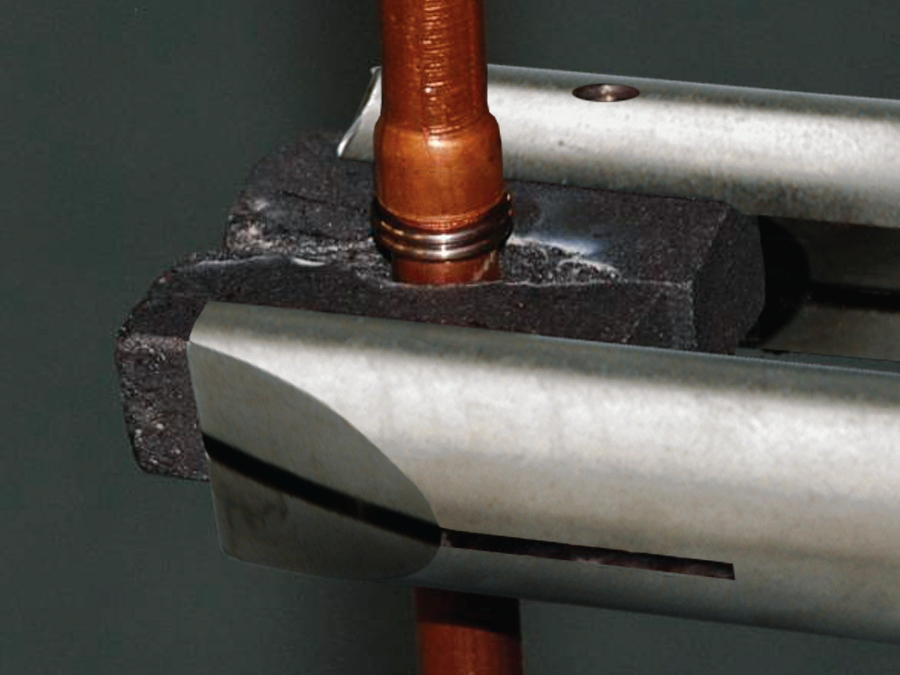

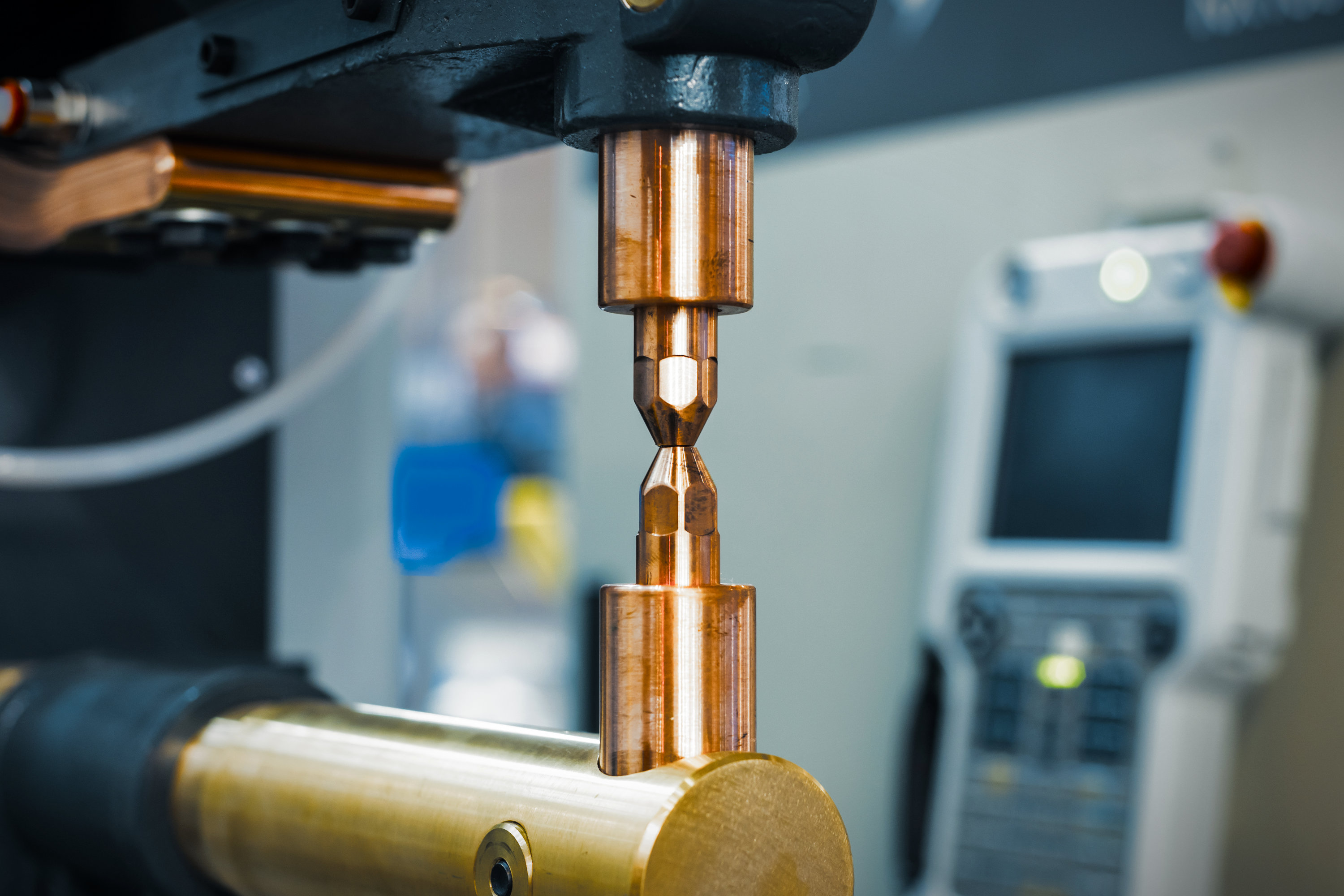

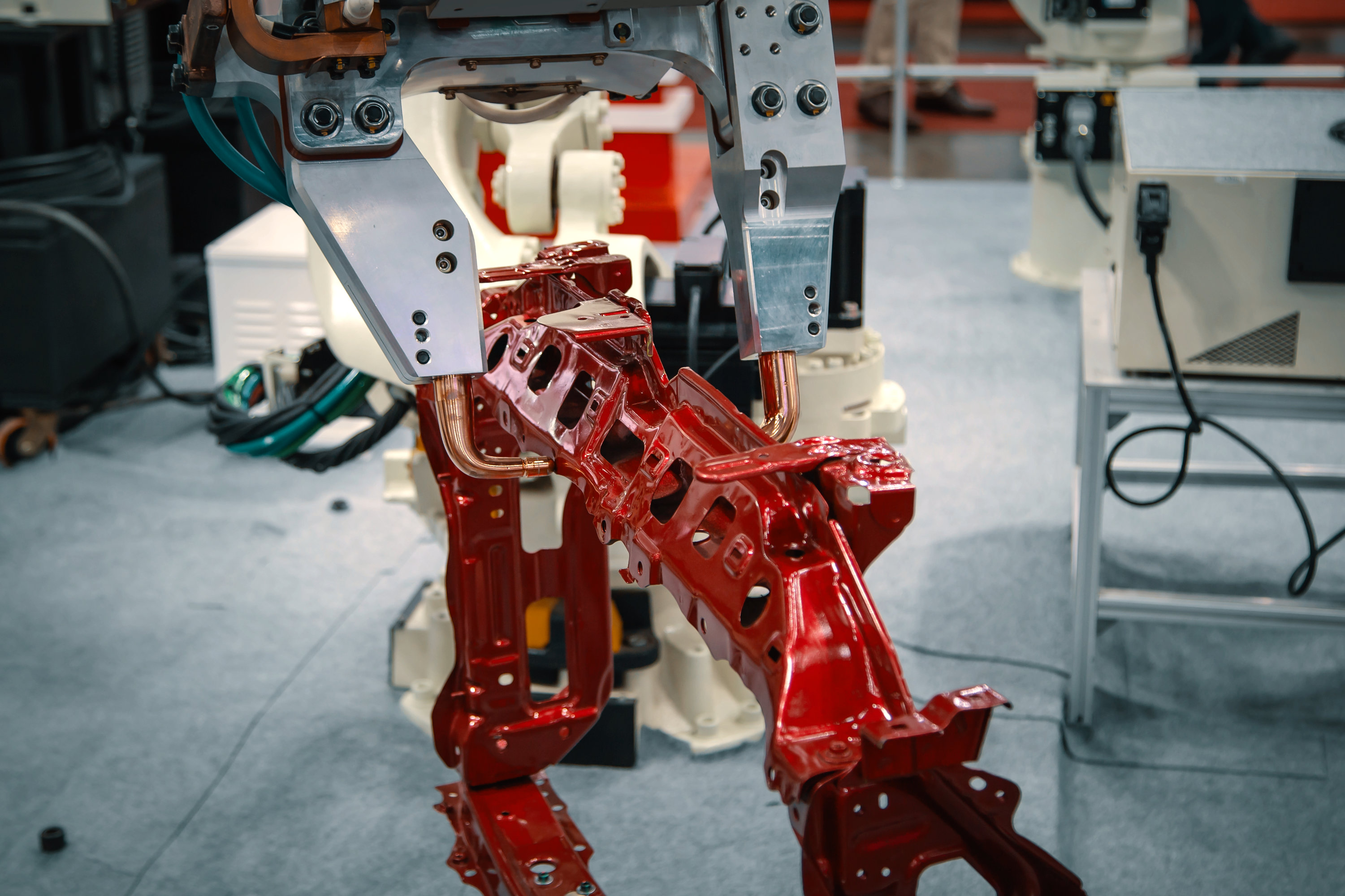

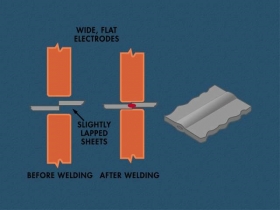

Lap seam welding is a type of resistance welding, also known as electrical resistance welding (ERW). Unlike arc welding, which uses gas, resistance welding uses a strong electric current to join two metal parts. The current heats the metal parts at the welding joint, causing them to melt and forge together. In seam welding specifically, the weld wheels (electrodes) apply the force and deliver the necessary current. After the weld absorbs heat energy from the molten weld joint, a weld nugget forms at the point of solidification. Applying pressure before, during, and after passing the electric current helps maintain the heat at the pressure application point. This process works well on low carbon steels, high alloy steels, stainless steel, aluminum, titanium, and more.